using a brinell hardness tester|brinell hardness tester instructions : Brand manufacturer The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested . 2 dias atrás · A ginástica rítmica brasileira já vem preparando a nova geração da modalidade. A seleção juvenil conta com novos talentos que foram escolhidos durante o .

{plog:ftitle_list}

Intensidade do Vento Fracos. Noite:: Muitas nuvens com pancadas de chuva isoladas . Direção do Vento SE-S. Intensidade do Vento Fracos. Arambaré-RS - 14/02/2024 - .

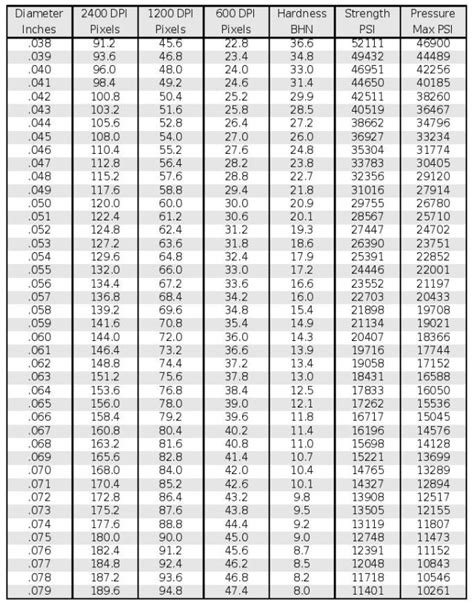

lee brinell hardness tester chart

In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .

Gas Permeability Test System purchaser

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, .The Brinell hardness test is based on the amount of resistance that a solid material offers when it is pressed into by force. Brinell’s method produces a small depression in the surface of some .

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition of the hardness value - Practical.Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index („Brinell test procedure“) in order to enable direct comparison of the measured hardness values.

The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic . Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .King Portable Brinell Hardness Testers are the most reliable, easy to use and affordable portable Brinell testers that are certified and calibrated per ASTM E-10 standards and the ONLY portable Brinell testers on the market that are .

The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.The Brinell hardness test consists of applying a constant load, usually in the range 500–3000 . N, for a specified period of time (10–30 s) using a 5 or 10 mm diameter hardened steel or tungsten carbide ball on the flat surface of a work piece.. The Brinell hardness number (HB) is then obtained as:Universal hardness testers are designed for hardness testing according to Brinell, Vickers, Rockwell and Knoop, as well as plastics testing and carbon testing.To cover all of these test methods, the universal hardness testing machine supports a wide load range. ZwickRoell universal hardness testers therefore provide a flexible solution with a load range from 0.3 to .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .

The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as:Our webshop offers online sales of accessories such as hardness test blocks, anvils, and indenters for Rockwell, Brinell, Vickers, Knoop hardness testing at an affordable price. Visit the webshop here. RECENT NEWS. Acquire the most accurate and easy way to . https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.A key component of Brinell hardness testers, these ball indenters are hard enough to make impressions on most metal. Made of carbide, they won’t deform as they press into hard material. Shallow indentations mean a material is hard and deep indentations show that it is soft. Use the diameter of the indentations created by these balls as part of the calculation to find your .

An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.A basic Brinell hardness tester with semi-automatic operation. NB3010 is a cost-effective Brinell tester using deadweights with a pneumatic load system to apply and remove the loads. Operates in most all Brinell scales.

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .In metallurgy: Testing mechanical properties .oldest of such tests, the Brinell hardness test, uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS. Hardness testing methods: Rockwell, Brinell and microhardness Heat treating has evolved into a highly complex, precise process that improves characteristics of metal parts. A critical component of quality heat treating is .The King Brinell Hardness Tester offers accurate, portable hardness testing for metallic materials, compliant with ASTM E-10 and E-110 standards. Easy to use, with a 3,000 kg load capacity.

The Newage Pin Brinell Hardness Tester is a simple and user-friendly hardness-tester, using calibrated shear pins to control the amount of load applied to the tested surface. Downloads + Manuals (1) + Pin Brinell Hardness Tester Manual; Data Sheets (1 .The Telebrineller Brinell Hardness Testing System is a valuable asset for a range of professionals and industries. Welding crews, in particular, will find immense benefit from its user-friendly design. It allows for efficient Brinell hardness testing .The Wilson BH3000 Brinell Hardness Tester stands as a robust Brinell hardness tester, boasting a wide range from 62.5 kgf to 3000 kgf. Crafted with rugged construction for resilience in challenging environments, this reliable hardness tester blends high rigidity and closed-loop load cell technology to ensure precise and secure load applications.The Wilson BH3000 Brinell Hardness Tester, with a robust 3000 kgf capacity, covers a wide range of loads from 62.5 kgf to 3000 kgf. Engineered for durability in harsh environments, it features rugged construction, heavy-duty clamping, and protection. The closed-loop system ensures quick and precise test results, while integrated hardness .

Using state-of-the-art load cell technology, the LCB3100 is a Brinell hardness tester that is versatile and easy-to-use. The operation is handled through a user-friendly touch-pad, virtually eliminating errors by removing the use of knobs and the stacking of weights that is typically associated with most testers.BRINELL HARDNESS TESTERS Brinell is used for hardness testing larger samples with a coarse or inhomogeneous grain structure. The indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically. DuraVista-40. Methods: Vickers, Knoop and Brinell hardness testing .

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. The diameter of the resulting permanent impression in the tested metal is measured and the Brinell Hardness .Versatile enough to test virtually any size and shape of metal specimen, these testers are easy to use. This portable Brinell hardness tester meets all international standards for Brinell testing including ASTM E-110, British Standard #240, Pt.2, Sect.1 and JIS Standards and is calibrated to 1/2 of 1% of load on equipment traceable to NIST .

Brinell Hardness Test. The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. The indentation diameter is then measured optically.The easiest and most portable hardness tester on the market. Use it in tight spots, right side up, upside down, or sideways! King Portable Brinell Metal Hardness Testers are the most reliable, easy to use, and affordable portable Brinell testers available and the ONLY portable Brinell testers on the market that are Directly Verifiable.

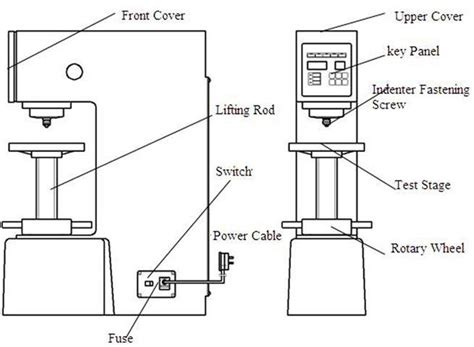

brinell hardness testing machine diagram

brinell hardness testing charts

Gas Permeability Test System purchasers

brinell hardness tester manual

webBenfica TV. Fundada em 2008, a BTV foi o primeiro canal televisivo de um clube português e mantém-se como o primeiro canal de clube do mundo a transmitir em direto e em exclusivo os jogos da equipa principal de futebol. Saber Mais . Estatuto Editoral . i++. Lorem ipsum. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod .

using a brinell hardness tester|brinell hardness tester instructions